INTECH has been a visionary leader in the field of Metal Based Additive Manufacturing in India. DMG MORI supplies customers from 42 different industries in 79 countries. With more than 12,000 employees the “Global One Company” is present worldwide at 157 sales and service locations – thereof 14 production plants. Our partner program “DMG MORI Qualified Products” (DMQP) allows us to offer perfectly matched peripheral products from one source. Our customer-focused services covering the entire life cycle of a machine tool include training, repair, maintenance and a replacement parts service. In addition, DMG MORI is offering its customers and suppliers an integrated digitization strategy with the open, digital platform ADAMOS. More than 10,000 DMG MORI machines fitted with CELOS have been supplied so far. With our APP-based control and operating environment CELOS as well as exclusive Technology Cycles and Powertools, we are actively shaping Industrie 4.0. Our technology excellence is bundled within the main sectors of “Aerospace”, “Automotive”, “Die & Mold”, and “Medical”.

Dmg additive manufacturing plus#

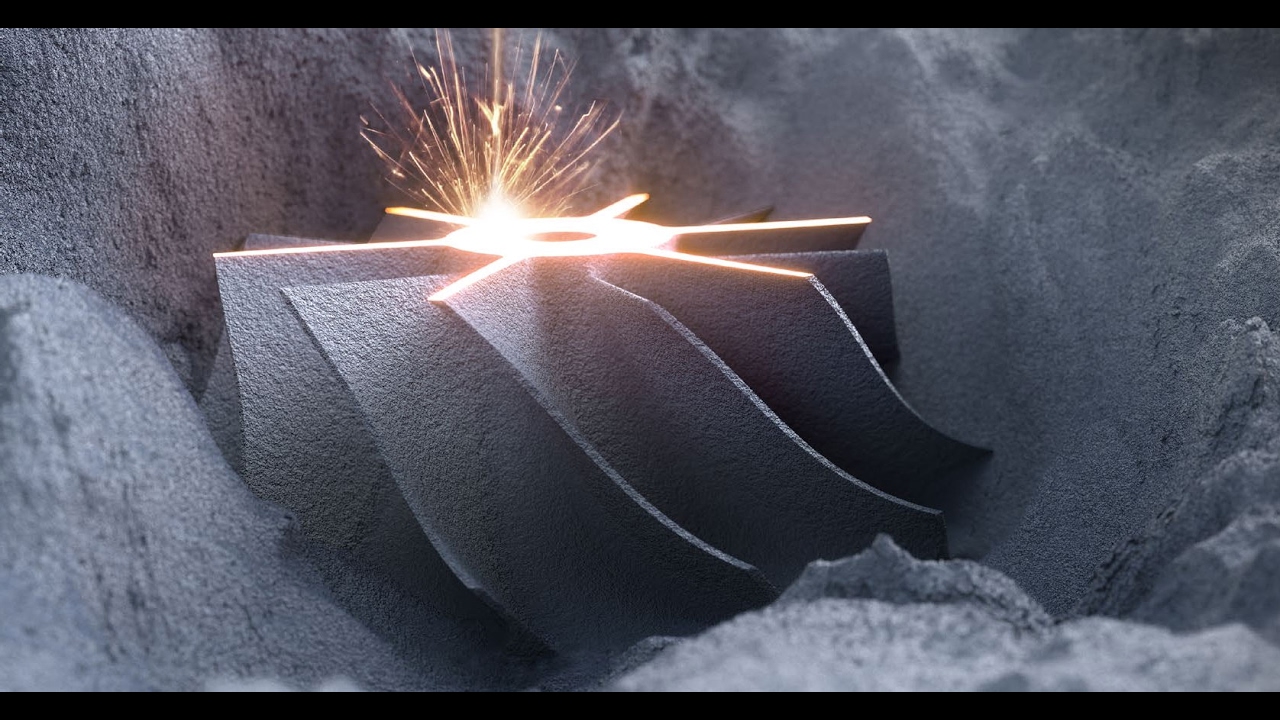

The range of products includes turning and milling machines as well as Advanced Technologies, such as ULTRASONIC, LASERTEC and ADDITIVE MANUFACTURING, plus automation and integrated technology solutions. As “Global One Company” − together with DMG MORI COMPANY LIMITED − we reach sales revenues of more than € 3.3 billion. A stepping stone towards the industrialization of ADDITIVE MANUFACTURING.ĭMG MORI AKTIENGESELLSCHAFT The Executive BoardĭMG MORI AKTIENGESELLSCHAFT is a worldwide leading manufacturer of machine tools with sales revenues of more than € 2.3 billion and more than 7,000 employees. This simplifies programming and results in a markedly improved surface quality as well as reproducible material properties.

The new OPTOMET-software automatically calculates the optimal process parameters.

Dmg additive manufacturing software#

INTECH supplies software solutions not only for the LASERTEC SLM series from DMG MORI but also for other products and customers using powder bed technology. OPTOMET is a game changer for the whole ADDITIVE MANUFACTURING market.” OPTOMET can also be applied to other key technologies of ADDITIVE MANUFACTURING, such as Direct Energy Deposition and Binder Jetting. Sridhar Balaram, CEO of INTECH noted, “Leveraging synergies is key, and the collaboration is a perfect fit of hardware and software.

We are actively pushing ahead with integrated series solutions along the whole process chain for generative manufacturing", says Christian Thönes, Chairman of the Executive Board of DMG MORI AKTIENGESELLSCHAFT. First time right – that means being fast towards the first good part. “With INTECH we strengthen our global footprint in India and accelerate innovative development in ADDITIVE MANUFACTURING. INTECH is committed to ADDITIVE MANUFACTURING and related software solutions, including machine learning and artificial intelligence for the Metal ADDITIVE MANUFACTURING industry and will soon release numerous solutions, aiding users with ease of machine operations and process control, producing quality components at optimized costs, thereby empowering customers to adapt this technology quickly. INTECH is considered as a pioneer in metal 3D printing in India. The 30% stake in the Indian software developer gives DMG MORI access to key software and technology know-how for generative production. DMG MORI and INTECH seal a cooperation in the field of ADDITIVE MANUFACTURING at the "formnext" in Frankfurt am Main, the leading international trade fair for ADDITIVE MANUFACTURING.

0 kommentar(er)

0 kommentar(er)